Overcoming Dips and Dressings Production Challenges

Manufacturers of dips and dressings operate in an intensely competitive marketplace where consumer tastes change frequently, stringent regulations, and the need for high standards of product quality and safety present significant challenges.

From smooth hummus to chunky salsas and salad creams, through to perennial favourites such as sour cream and chives or thousand island dressing, the dips and dressings category is vast. However, regardless of the type of dip or dressing being produced, every manufacturer faces the same issues.

Maintaining Product Quality and Shelf Life

Every product that is produced must be identical. It has to have a consistent texture, flavour, and mouthfeel. Even distribution of particulates and preserving freshness are essential, especially as dips and dressings often contain sensitive ingredients such as oils and eggs, which are prone to spoilage. With this in mind, cost-effective batch pasteurisation and robust seal integrity in packaging are essential to ensuring maximum shelf life and food safety.

Packaging and Leak Prevention

Leaks, seal failure and weak barrier performance can tarnish both product quality and brand reputation. Irrespective of the type of packaging used, it must feature leak-resistant seals and sturdy construction to protect contents during transport and storage.

Tamper-evident features and easy-to-handle, stackable designs are now essential, as they ensure food safety and provide an attractive presentation.

Regulatory and Sustainability Pressures

Food safety regulations are complex and change often, ensuring updated allergen and nutrition labelling is prominent requires packaging lines to be flexible and adaptable. In recent years, there has been a growing emphasis on and importance of sustainability. Manufacturers are constantly seeking ways to minimise waste and reduce energy and water usage, all while delivering eco-friendly packaging solutions. These measures not only appeal to consumers but also save money.

Production Line Efficiency and Traceability

Automated packaging machinery must be able to accommodate the varied product viscosities and batch sizes encountered in dips and dressings production. Downtime caused by operational gridlocks or inefficient line configuration can significantly reduce margins and profit. The importance of end-to-end traceability of both ingredients and finished products is now a standard request from major retailers and auditors.

Established in 2009 by a team of experienced engineers, Flexi-Pak has a long and proven track record of working with dips and dressing manufacturers. For directors, project managers, and engineering managers seeking a partner to design, manufacture, and commission new machinery or a new line to pack dips and dressings, Flexi-Pak stands out for several reasons.

Industry-Tailored Packaging Machinery

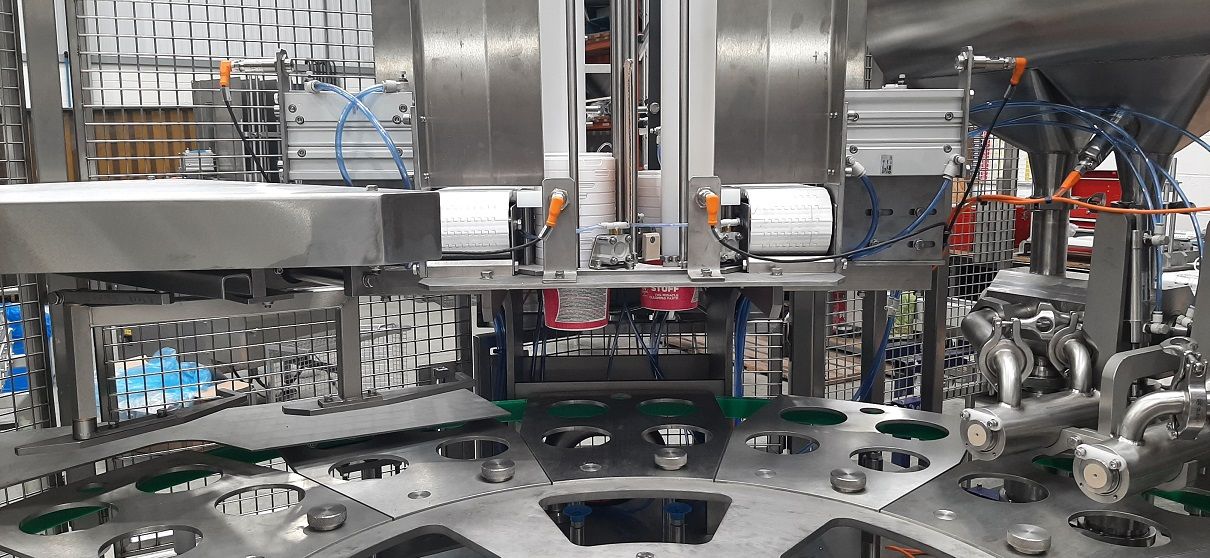

Flexi-Pak’s solutions include high-speed form-fill-seal and thermoforming lines, designed for creamy, chunky, and liquid-based dips and dressings. The company’s systems support a wide range of pack formats, from individual portion cups to large catering tubs, all with secure lids and leak-resistant seals.

High-Integrity Packaging

Flexi-Pak’s machinery delivers exceptional seal robustness using advanced heat sealing or induction sealing technologies. Leak-proof containers and tamper-evident features ensure dips and dressings remain safe throughout the entire supply chain, enabling food manufacturers to meet the strictest customer and retailer standards.

Flexible and Customisable Solutions

Whether you’re responding to seasonal product trends and launches or varying run sizes, Flexi-Pak machines are engineered to minimise changeover times and adapt to your SKUs. We offer custom tooling and rapid setup for new shapes or labelling, allowing for both branding and compliance labelling without disruption.

Sustainability

Our lines are optimised for minimal energy use, material waste, and efficient water usage. We support packaging developments, including rPET, PLA, and fully recyclable options for eco-conscious brands.

Outstanding Service and Support

Our team is based in Gainsborough, Lincolnshire, and as such, can deliver comprehensive project support, from line layout and integration to staff training, ongoing maintenance, and rapid-response services.

If you’re considering investing in a new line or machine to pack dips and dressings and need a reliable, robust, and efficient solution that will allow you to comply with current allergen labelling, traceability, and sustainability requirements, and scale up easily as you grow, then Flexi-Pak is the perfect partner.